VisioKrom®, the colored additive for visualizing anticorrosion treatments

The simple, effective control solution for

your anti-corrosion treatments

Discover VisioKrom®, the colored additive developed by OliKrom to improve the visualization and traceability of industrial processes. Custom-formulated, it enables immediate visual control of areas treated with colorless anticorrosion, without disrupting technical performance.

A simple, reliable solution compatible with industrial requirements for aeronautics, energy, transport and much more.

Discover VisioKrom® technology, its history and its use in industry

Chrome 6: the historical benchmark

For many years, the fight against aluminum alloy corrosion has been based on chemical conversion surface treatments.

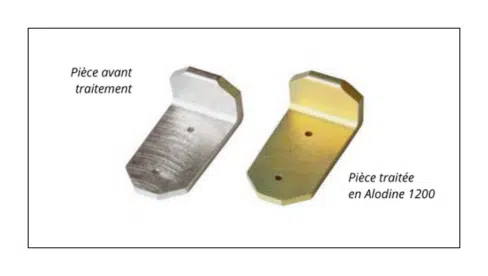

For decades, hexavalent chromium (Cr6+) has been the benchmark for anticorrosion protection of aluminum alloys, notably via chemical conversion treatments such as Alodine 1200.

Its advantage: excellent corrosion resistance and electrical continuity between contacting surfaces. Another major advantage was its characteristic yellow coloring, enabling quick and easy visual inspection.

Changes in regulations

In 2006, European REACH regulations imposed the phasing-out of hexavalent chromium due to its high toxicity. Classified as CMR (Carcinogenic, Mutagenic and Reprotoxic), Cr6+ represents a major risk to human health and the environment.

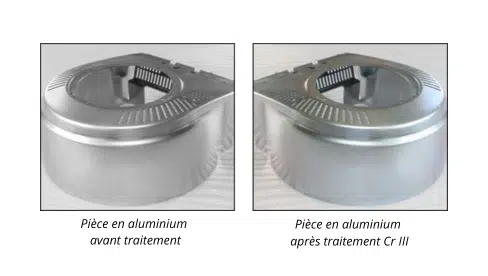

Aujourd’hui, les nouveaux traitements anticorrosion à base de Chrome 3+ sont conformes aux normes environnementales. Ils présentent toutefois l’inconvénient d’être incolores, rendant donc les contrôles qualité visuels plus difficiles.

Comment s’assurer que la pièce a bien été traitée ? Comment valider le niveau de dépôt ?

VisioKrom répond à cette problématique de contrôle visuel.

VisioKrom® was born of a concrete need observed in the field: how to visually and quickly ensure that a treatment has been applied correctly? In many industrial sectors, Chrome 3-based treatments are colorless and invisible once applied. This complicates the validation of operations and can lead to errors or non-conformities.

OliKrom is therefore initiating a research program to develop a colored additive formulated to be added to chemical conversion treatments without altering their properties. To move from laboratory to industrial scale, OliKrom launched the DANCO program (Detection of the Application of an ANtiCOrrosion surface treatment), supported by the Nouvelle-Aquitaine Region. This collaborative project brings together three regional companies: OliKrom, SECO (Aegis Group) and THALES DMS. The aim is to offer the aerospace industry a concrete solution for securing the quality control of chrome-free conversion treatments.

Before 2020: Identification of needs in the field with several manufacturers. Literature review on Chrome 6: over 5 years of research in our R&D laboratories.

2020: Laboratory-scale proof of concept in collaboration with Thales DMS

2023: Move to individual pilot and industrial-scale testing to develop a colored additive formulated to be added to chemical conversion treatments without altering their properties.

2023: Launch of the DANCO program alongside SECO (Aegis Group) and THALES DMS, a program supported by the Nouvelle-Aquitaine Region.

2025: Industrial validation of VisioKrom® , our colored additive, by SECO and L'Electrolyse, and marketing of our solution. VisioKrom® sets out to conquer the international aerospace and military markets.

our product catalog

Find out more about our VisioKrom® product and all the technical information on our admixture.

A solution designed and manufactured in France

VisioKrom® technology is designed, formulated and produced at our Pessac plant in the Nouvelle-Aquitaine region of France. This choice guarantees our customers complete traceability, optimum responsiveness and controlled quality. Made in France is at the heart of OliKrom's approach, in a spirit of proximity, innovation and industrial sovereignty.

La technologie VisioKrom® est conçue, formulée et produite dans notre usine de Pessac en Nouvelle-Aquitaine. Ce choix garantit à nos clients une traçabilité complète, une réactivité optimale et une qualité maîtrisée. Le Made in France est au cœur de la démarche d'OliKrom, dans un esprit de proximité, d'innovation et de souveraineté industrielle.

When you choose VisioKrom®, you're opting for reliable, controlled technology, 100% Made in France, dedicated to industrial performance and safety.

![]()

CONTACT US

We will get back to you as soon as possible..

"*" indicates required fields