Research and Product Development Department

Scientific innovation at the heart of OliKrom's strategy

At OliKrom's research and process departments, we place the product development and the mastery of smart materials (pigments, inks & paints) at the heart of our strategy.

Each year, more than 30% of our investments are devoted to research and product development. The ambition of our R&D center is to always be at the forefront of smart coatings.

We are constantly improving our technologies in order to offer you the best solution, excellence in research and product development, as close as possible to your needs.

A team of experts in smart materials science and research and product development

Our R&D team consists of PhDs and engineers with expertise in chemistry, physical chemistry, photochemistry, thermodynamics of phase transition phenomena and research and product development.

Through these skills, our research center is committed to scientific excellence and creativity to develop the best innovative technology with color change or optimized luminescence properties.

Over the years, we have acquired a unique know-how, that of "making colors talk", of programming colors in a customized way.

This expertise in color intelligence allows our teams to innovate daily to meet new uses. We implement new synthetic ways (organic, hybrid, inorganic) and develop new intelligent products by adjusting the switching speed, the triggering threshold, the optical contrast, etc.

Every day, we create new security features and innovative solutions in response to environmental or performance issues.

Each year, more than 40% of our research and product development programs are carried out internationally.

A 90% success rate for our proofs of concept

Today, more than 70 industrialists from all sectors trust us every year. Beyond this recognition, our greatest pride is to succeed in our feasibility studies 9 times out of 10.

This performance validates our research and product development methodology and the rigor that drives us.

The agility of our teams allows us to be an integral part of complex scientific and product development programs over several years as well as the launch of new collections in extremely short time frames.

The TRL (Technology readiness level) increase, a proven process

Our research department is the first actor to take part in the product development process. The other OliKrom departments, the Process office, the Production Unit and the Assistance & Consulting Center, will then take over.

At each stage, our mission is to advise you in order to make the right choice, to evaluate your request and its options in order to find the best compromise between the expression of your needs and the real potential of intelligent materials, to transform your projects into products in the shortest possible time!

In this speed race for innovation, we regularly exchange with your teams to anticipate any future difficulties in the industrial integration of your product. We also guarantee the utmost confidentiality to our industrial partners by signing non-disclosure agreements (NDA), research contracts.

This culture of pragmatic innovation allows us to have technologies already on the market and others in the imminent marketing phase. A whole series of projects are already preparing our future growth drivers.

The main stages of a rise in maturity (TRL 1 to 3-4)

The bibliographic study

Depending on the type of your request, the first step entrusted to our research office is often the state of the art. This is an excellent tool to evaluate the relevance of a breakthrough product development.

This bibliographic study is carried out from international databases of scientific journals, patents and economic data.

At the end of this study, our research team analyzes all the scientific works and presents you with a hierarchy of data and potential solutions according to technical feasibility, economic dimension, regulatory constraints, etc.

This allows our research engineers to identify an "embryo" of a solution, to evaluate the existence, or not, of a basis, more or less remote, to obtain the desired property.

Thus, as close as possible to your team, we bring you the advice to initiate, or not, the transformation of your "innovative idea into product".

The proof of concept

The next step for our research department is the proof of concept. This feasibility study takes place either at the end of the state of the art, or directly after the realization of the specifications of the future product.

To carry out our product development process, the first phase is voluntarily divergent, without constraints or brakes. The aim is to allow the first research steps towards feasibility to germinate, without any constraints. Generally, our R&D teams explore a multitude of synthetic routes, classes of coatings, intelligent properties... This research freedom is essential to hatch "the" solution to your problem.

Once this solution has been identified, it is challenged, amended and modified. We then enter the second phase of the feasibility study, the convergent approach known as "constraint": our research and product development office makes the necessary modifications to integrate part of the technical and environmental constraints of your request and thus validate its feasibility.

The optimization stage

This time, the product development objective is to be as close as possible to your specifications. Our R&D engineers team fine-tune "the solution" by integrating one by one the technical, economic, regulatory and environmental constraints related to the project.

This leads our research and product development office, for example, to modify the elementary bricks to optimize the switching threshold of the optical properties according to the targeted external stimulus: temperature, light, pressure, presence of a solvent, a gas, or a pH variation. In other cases, our R&D team have to rework the optical response: absorption, excitation, emission wavelength.

Sometimes, we have to completely revisit the scientific idea identified during the "proof of concept", and modify the chemistry involved to satisfy economic and/or environmental constraints (the origin and/or nature of the products).

This is a real engineering process that allows us to program the molecular entity at the base of the intelligent product and to take into account the dimensions of an innovation. This process requires several "round trips" between the synthesis and characterization phases to finely optimize the product with the optimal targeted property.

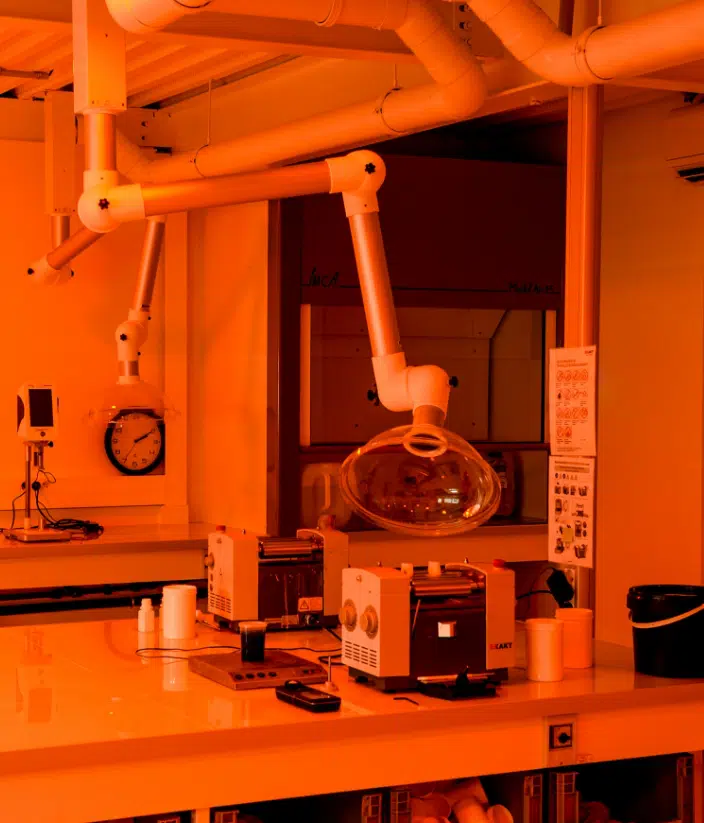

Our technical platform of Research & Product Development

Our R&D department has a technical platform of more than 1000 m2, of high scientific level, to realize all the stages of synthesis and products characterizations.

Our research and product development department is equipped with all the necessary equipment for the synthesis of organic, hybrid and inorganic products:

- Chemical reactors, stirrers, mills, mixers,

- Muffle ovens (high temperature), Centrifuges,

- Suction hoods, Ovens...

We also have a range of equipment for characterization of very high scientific level. The properties of smart products (pigments, inks and paints) with color changes and luminescence are studied using specific equipment:

- Absorption spectrometer, fluorometer, lidar,

- Colorimeter, luxmeter, reflectivity, retroreflectometer,

- Viscosimeter, rheometer, microscope,

- UV aging chambers, elimination chambers,

- Taber abrasion tester, ball dropping device...

![]()

CONTACT US

We will get back to you as soon as possible..

"*" indicates required fields