A new generation of smart materials and structures

Smart materials and structures, a unique and patented know-how

OliKrom is the industry leader in customized smart materials and structures.

Every day, we design and produce custom intelligent pigments and dyes, and formulate inks and paints.

This breakthrough innovation is the result of more than 15 years of fundamental and applied research.

Why are OliKrom's smart materials and structures unique?

Our team of doctors, engineers and operators, experts in intelligence of color, masters the most advanced scientific concepts in Materials Science, Thermodynamic, Photochemistry, Formulation of intelligent coatings, Chemical and Industrial Engineering...

This unique expertise allows us to structure and chisel matter by molecular engineering to give it intelligent properties. Like a mason or a goldsmith, we build the hybrid architecture by selecting the right elementary bricks (organic/inorganic molecular product).

This allows us to control the change of color and/or emission depending on the desired external perturbation (temperature, light,...).

This generation of intelligent materials and coatings is the result of an acquired and patented know-how. We own more than ten patent and trademark portfolios, and have several exclusive licenses.

We tailor intelligent materials to your specifications

We have at our disposal a set of elementary bricks allowing us to adapt the reactivity of the pigments and coatings according to your project.

We can program the reactivity of the material by molecular engineering to induce a change of the optical properties according to the project:

- with the temperature: thermochromic property,

- with the light: photochromic and luminescent property,

- with the pressure: piezochromic property,

- with the presence of a solvent or a gas: chemochromic property.

This unique know-how allows our teams to intervene and transform "concepts" into "intelligent materials", some of which are already commercialized.

The art of selecting the right building blocks

Optimize the triggering threshold

The first and most important step for intelligent materials is to define the process responsible for the change in property: temperature, light, pressure... Then comes the most delicate part: adjusting the triggering threshold and maintaining this property until the finished structures.

For a thermochromic materials, this may mean changing color at 25°C, for a photochromic material it may mean controlling the speed of writing and erasing under light, or even for a chemochromic material it may mean adjusting the reactivity and selectivity to a gas...

The role of our chemists in our Research Department is to select the most suitable physical process adapted to your project. We have at our disposal a wide variety of smart materials and our internal research is continuously leading us to enrich this alphabet by exploiting new mechanisms of isomerization, cyclization (or ring opening), electron transfer, proton transfer, hydrogen atoms and/or spin state...

Program reversibility or irreversibility

To obtain an optimal intelligent material, it is quite a balance to find. A simple modification of the coating (matrix & pigment) can lead to a reversible or irreversible property. Today, there is a multitude of intelligent pigments (and dyes) which are transformed by the contribution of an external energy and obey the laws of the phenomena of phase transition.

Some are accompanied by a complete disruption of the chemical structure with the passage of a solid form to a liquid form, for example an ice cube that turns into water around 0°C. Others show much more subtle changes. They are able to show a change in color without apparently any other changes. In reality, at the molecular level, a structural change has occurred: for example, a change in coordination from an octahedral to a tetrahedral site, a shift in the plane of atoms in the structure, etc.

To generate an irreversible effect, the strategy is to select a physical process (responsible for the modulation of the color) which will be accompanied by a very strong structural constraint to avoid any reversibility. On the other hand, to obtain a reversible property, it is necessary to select mechanisms with very low structural constraints at the molecular level.

For our teams, everything is in the adjustment of the chemical architecture to design advanced materials.

Controlling the fatigability of the process

During their ON/OFF modifications, some intelligent materials show a phenomenon of fatigability: the process does not return to the initial state.

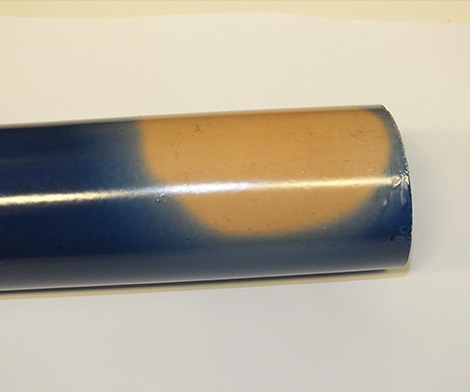

As an illustration, let us take the case of a smart material which changes color from blue to white. The presence of a fatigability phenomenon is observed when the coating starts to show an intermediate bluish color during the ON/OFF modification cycles. In fact, certain molecular entities do not have any more the capacity to change state. They remain blocked in their initial state. We end up with a mixture of blue beads able to change into white and others blocked in their blue form.

This phenomenon of fatigability during the cycles of modification ON/OFF is the consequence of a bad definition and design of the advanced product. It resides a too strong structural constraint which generates little by little a degradation. This can come from the smart pigment and/or the matrix itself.

For some industrial applications, this phenomenon of fatigability is sought. Our teams exploit this property to create and design customized fatigue indicators with a cumulative effect. The use of such smart materials concerns many sectors and applications: in particular in the field of predictive maintenance in industry, or for the expiration of an article in the fields of health, food, automotive industry...

Each request of intelligent materials has its specificities

We have a wide range of intelligent pigments and coatings at our disposal and we don't have a catalog on the shelf.

Because your expectations, your industrial process, your matrix are specific, it is impossible to provide a sample before designing it for you.

At OliKrom, each Smart Material is designed and produced to meet the precise specifications of our industrial partner.

We have the basic elements to design a custom intelligent material, then we integrate each of your constraints (Technical, Economic, Regulatory, etc.) to produce the right product.

Our teams are at your disposal and we will adjust:

- The nature of the colors (wavelengths) involved,

- The reversible and/or irreversible character,

- The switching speed and the fatigability issues as function of energy: temperature, light, pressure...,

- The insertion of the intelligent pigments in a formulation without altering the properties,

- Industrial scale production of smart materials and structures: inks and paints.

Smart materials: a societal evolution

Our societies have always adapted and perfected themselves. The first civilizations were built with natural products such as wood, stone, leather, bone, horn, linen or hemp. We then experienced the emergence of plastics and composites with implications all around us, in the building, automotive, aeronautical, sports and military sectors.

Today, we are entering the third generation of multifunctional coatings, capable of adapting to their environment. This is the world of smart products and applications. This is a real revolution for the 21st century, just as important as the revolution in communication or biotechnology.

![]()

CONTACT US

We will get back to you as soon as possible..

"*" indicates required fields