Predictive maintenance

Make colors speak to alert in real time

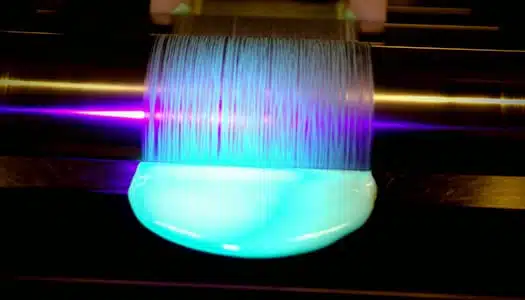

To develop predictive maintenance, we make "colors speak" to anticipate future failures on an equipment, a product, a system. Our objective is to guarantee the safety and reliability of the industrial tool.

With the birth of intelligent materials, the color of a coating is no longer fixed: it can change with its environment and be programmed on demand to develop predictive maintenance tools.

The time for corrective maintenance is over

Gone are the days of corrective maintenance, which consisted of repairing - or even replacing - a part once a failure was detected. This type of maintenance led to late intervention, and therefore to production line stoppages.

Gone is also the preventive maintenance which consisted in planning in advance a control at regular intervals (as the revision of a vehicle) to reduce the occurrence of a breakdown. Scheduled interventions without any real problem is experienced as a questionable additional cost.

Today, we are witnessing a new mutation of the sector with the development of predictive maintenance tools. Alongside manufacturers, we are developing intelligent solutions to anticipate failures by taking into account the data specific to each installation, in real time and continuously.

To do this, we exploit the richness offered by smart materials. The options for creating devices (sensors, indicators, components, etc.) that interact in real time with their environment are limitless.

The material can become reactive to temperature, light (photochromes and luminescents), pressure, presence of a solvent or a gas for monitoring components, industrial operations...

Monitoring a failure on line, predictive maintenance of the industrial tool

Visual or automated detection, the art of predictive maintenance

Depending on the predictive maintenance needed to monitor an equipment, we adjust the optical response of materials.

- Sensors detection can be visual, so an operator can identify that impending failures are about to occur on a production equipment.

- The analysis of the sensors can also be automated to be monitored by drone, remote monitoring...

As an example of failure identification and development of predictive maintenance tools, the use of a functionalized temperature responsive coating applied to the exterior of an industrial chimney can be used to monitor its proper operation. The monitored color change will alert that a malfunction is taking place due to wear of the protective wall.

Everything happens at the material level. The selection of the right molecular components allows our teams to program the switching phenomenon so that it is accompanied by a modification of the optical properties in the ultra-violet, visible, near or far infrared spectral range.

An adapted control of predictive maintenance: not too early, not too late

When predictive maintenance works effectively as a prevention strategy, it is performed on machines only when necessary. That is, just before a failure is likely to occur.

This results in several cost savings: reduced equipment maintenance time, reduced production hours spent on maintenance, reduced cost of spare parts, and extended equipment life.

The notion of kinetics for material scheduling is therefore extremely important to ensure that the alarm is not raised too early or too late. Our role is to adapt the mechanisms involved to obtain the right timing, to develop the optimal predictive maintenance tools :

- We program the change of optical property at the right triggering threshold with a reversible or irreversible effect.

- We even take advantage of the fatigue of certain materials to create a programmed time delay. The change of color only occurs after a certain number of cycles, like the taking into account of the temperature to indicate the need for maintenance.

Autonomous coatings for predictive maintenance

Some constrained industrial environments require monitoring failures without power supply. In response to this need, the mechanisms used to change the color and/or luminescence of smart materials are thermodynamic. This is a passive solution on an equipment: no electricity is needed, the color change occurs only when the threshold is crossed.

Everything is in the initial programming of the material, the smart coating, to present the right triggering threshold: temperature, light intensity, level of detection of the targeted gas... It is consequently a robust technology to develop predictive maintenance tools which contrasts with the electronic fragility of electronic sensors: breakdowns, hacking, etc.

As an example of predictive technology, the use of thermochromic coatings (sensors) can replace thermocouples and/or thermometers. It is today an industrial reality for predictive maintenance of production equipment.

In 2021, the GRTgaz group was looking for a partner capable of developing predictive maintenance tools in the field of corrosion. The objective was to provide an innovative operational response to alert the formation of corrosion on overhead pipelines. Currently, monitoring requires careful inspection by GRTgaz agents in the field.

OliKrom company has been selected as part of GRTgaz's "Open Innovation Factory". For Ahmed Fakhry (research engineer, Pipeline department, RICE): « OliKrom convinced us by its clarity and the relevance of its proposals for developing a predictive maintenance solution. They are experts in the field of smart pigments and we were looking for a predictive solution, capable of changing color when corrosion appears. This technology will enable operators to recognize the onset of corrosion on overhead structures thanks to changes in color or luminescence status. This will reduce the cost of repairing and rehabilitating the pipes. »

Photoluminescent signage

Securing night-time movements on an industrial site: secure pathways, dangerous areas, evacuation routes, stairways, etc.

Nature : Solvent or aqueous phase

Support : Bitumen - Cement - Metal

Application : Spray - Brush - Roller - Aerosol can

Smart paints

Customized product: paint that changes color according to temperature, light, shock, solvent or gas.

Nature : Solvent or aqueous phase

Support : To be defined according to the project

Application : Spray - Brush - Roller - Aerosol can

Smart inks

Custom product: color changing ink depending on temperature, light, shock, solvent or gas.

Nature : UV solvent or photocurable ink

Support : To be defined according to the project

Application : Silk-screen printing - Flexography - Pad printing

![]()

CONTACT US

We will get back to you as soon as possible..

"*" indicates required fields