Photochromic materials: pigments, inks, paints

Materials that change color with light

OliKrom is the leader in custom photochromic products with changing color under optical excitation.

Every day, we design and produce custom photochromatic pigment and dye, and formulate photochromatic ink and paint.

We adjust the properties (color) and reactivity (speed, sensitivity) of the photochromatic materials according to the optical source (energy, wavelength), laser (continuous, pulsed), solar light... and the deposition techniques (screen printing, spray...).

15 years of expertise in the field of photochromism

Our custom photochromic materials

In the world of photochromism, we have made the strategic choice of "made-to-measure". The examples of commercial photochromatic pigments are numerous, as are the mechanisms at the origin of photochromism. However, each generation of photochromatic materials has its advantages and limitations.

As soon as you entrust us with a request of photochromatic ink & paint, our teams study your specifications, your industrial environment, your regulatory and economic constraints, etc.

This analysis allow us to select the generation of photosensitive products best suited to your needs and your deposition technique.

We then produce your custom-made photosensitive pigment and/or dye, then formulate the ink and/or the photoreactive paint.

The photo-induced effect will be controlled at each step, and rectified if necessary, to deliver at the end of the development process a photochromatic ink & paint that meets your expectations.

Our custom photochromic pigments and dyes

With 15 years of experience in the world of photochromism, our expert chemists, physicians and engineers master all photochrom families: organic, hybrid, inorganic.

We have a wide variety of photosensitive materials: organic (such as stilbenes, camphor, o-nitrobenzyls, osazones, semicarbazones, etc.), hybrid or inorganic derivatives (such as metal oxides, alkaline earth compounds, metal halides).

Our internal research is continuously leading us to enrich this alphabet by exploiting structural modification mechanisms of isomerization, cyclization (or ring opening), electron transfer, proton transfer, hydrogen atom transfer and/or spin state...

With this library of photochrom derivatives, we are able to induce a wide range of effects, colors and reactivity (sunlight, optical sources,...):

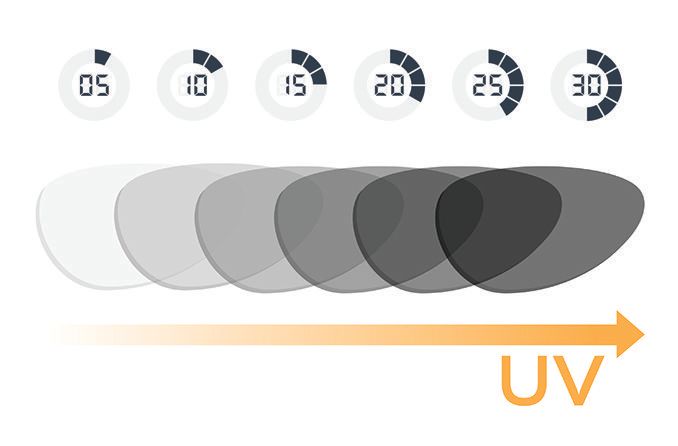

- The photochrom response can be positive. In this case, the photochromic transition is accompanied by a coloration. The stable colorless or pale yellow form becomes colored during irradiation. For example, glasses and lenses that darken with the brightness of the sun to improve vision (comfort, sports, etc.).

- The photochrom response can also be negative, if any, with fading of photochromic products. The colored form A turns into a colorless form B. There are also examples of photoinduced transition between different colors.

From experience, two main classes of photochromic materials can be distinguished, depending on whether the property is reversible or irreversible:

Reversible photochromism

Transformation of property at a defined irradiation power, return to its original form when the illumination returns to its initial level. Possibility to customize the colors of the two isomers, the excitation absorption wavelength, the photochromic speed.

Irreversible photochromism

Definitive transformation of properties at a defined intensity threshold. Possibility to adapt on demand the light intensity threshold, the excitation absorption wavelength (ultraviolet, visible, infrared) or the photoinduced speed.

By molecular engineering, our team will program the photoinduced material as closely as possible to your project. To obtain the reversible or irreversible character, we will finely modulate the proportion of organic entities or inorganic entities within the photosensitive material:

- The organic material brings the degree of flexibility essential to ensure the speed of the phenomenon and the absence of fatigability.

- The inorganic component provides the "light resistance".

We will then adjust the color modification threshold, its speed, the colors involved... It is a subtle balance to create, to control and adapt the chameleon property according to your need, your targeted product.

Our custom photochromic inks and paints

In the field of photochrom pigments and dyes, the formulation stage (preparation of inks and paints) is critical. It is too often neglected due to a lack of knowledge of the physical processes involved: material science, phase transition, thermodynamics...

We know that the application of shear forces associated with the passage of the tricylinder and/or the ball mill can alter the crystallinity of photo-reactive particles. That a simple additive, that a simple variation of the polarity of the medium and/or of the pH can affect the thermodynamic equilibrium at the origin of the phenomenon of color change, or even the optical properties by modifying the respective positioning of the electronic states.

This ultra-reactivity of pigments and/or photochromic dyes to their environment, obliges us to check at each stage of the formulation, the maintenance of the smart property.

This also explains why :

- we create our own photosensitive pigments (dyes)

- but only supply our materials in the form of inks, varnishes and paints,

- to guarantee the performance of the coating and the application (spray gun, screen printing, airbrush...).

All our photochromic coatings are manufactured on our ISO 9001 certified industrial site in Pessac, France, according to rigorous manufacturing processes and under the permanent supervision of our quality manager.

Each batch is traced and accompanied by a performance certificate. Any deviation is recorded, analyzed and corrected as part of our continuous improvement policy.

Photochromic ink

Nature: solvent-based or UV photocurable ink

Support: to be defined according to the project

Application: Screen printing - Flexography - Pad printing - Offset

Photochromic paint

Nature: solvent or aqueous phase

Support: to be defined according to the project

Application: Spray - Brush - Roller - Aerosol can

Our unique know-how in photophysics allows us to adjust the performance of the process: speed of photo-commutation, threshold of property change of inks and paints, positioning of the wavelength in the ultraviolet, visible and/or infrared.

One of the characteristics of photosensitive materials is to involve, during the mechanisms of excitation and relaxation, a stable state A which is transformed by irradiation towards a more or less metastable B level of different absorption spectrum. Depending on the molecular structure, the B form can be converted back to the A form by thermal and/or photochemical means.

This knowledge of the mechanisms makes it possible to avoid the pitfalls frequently encountered with photochrom materials: instability and/or fatigability of the phenomenon, non-optimal optical properties, speed of inscription and erasure too slow or too fast, dependence of the kinetics with the temperature, combination of the thermochromic and photochromic effects, degradation of the properties during the formulation (ink & paint) and/or the industrial process, sensitivity to the ultraviolet rays, etc

In the world of photochromism, our team accompanies you from A to Z, from the idea to the final photochrom product. This allows us to intervene effectively at each stage of the project: research and development, pre-industrialization and industrialization.

Space & Defense

In aeronautics and defense, the use of photochromic derivatives makes it possible to create coatings with enhanced properties, interactive with their environment to counter laser aggression (increased vision protection on glass, lenses...) or induce camouflage, like a chameleon in nature.

In the space domain, photochromic and thermochromic properties of materials are two mechanisms particularly studied to capture solar energy and/or to protect themselves from the sun's rays by changing color...

Health & Nature

In the field of ophthalmology, the uses of photosensitive coatings are mineral or organic lenses for glass, which darken in reaction to ultraviolet wavelength for sunlight protection.

- Mineral lenses usually incorporate a silver halide compound in their structure. Under UV exposure (sun), the silver-halide bond dissociates in favor of an Ag-Ag interaction, and the glasses and/or lenses darken. This metastable organization fades away and the silver-halide bond reforms as soon as the UV exposure is stopped, restoring the clarity of the lens.

- Organic lenses are usually coated with a layer of oxazines. Under the effect of UVs, a structural transition takes place and the glasses and/or lenses darken. As soon sunlight excitation is stopped, the initial thermodynamically stable state is restored and the clarity of the glass is regained.

Cis and trans isomers do play important biological roles. The early stages of vision occur in specialized ocular cells, the photoreceptors. The pigment in these photoreceptors, rhodopsin, consists of the protein opsin and the chromophore retinal. When sun illumination hits rhodopsin, an cis-trans photoisomerization reaction occurs in retinal that changes the shape of the chromophore and the entire protein. This cis-trans photoisomerization process triggers the visual signaling cascade that ultimately transmits an electrical signal to the brain.

Nature also provides many examples of photochemical and/or cis-trans photoisomerization processes. For example, during photosynthesis in green plants, the pigment molecules chlorophyll absorb sun photons and thus provide the energy for the synthesis of carbohydrates. Sunlight also promotes the photodissociation of ozone in the atmosphere. Ozone absorbs this radiations and thus helps protect us from dangerous sun ultraviolet rays.

Industry & Construction

- In the building industry, chameleon coatings (paint, ink...) offer a multitude of opportunities for protection (modulation of absorption, colors): dynamic glazing, photochromic agricultural greenhouses...

- In the industrial field, the use of irreversible photochromism allows the watermarking of parts by laser treatment (authentication, anti-counterfeiting, personalization of an object...). The modulation of the optical properties (colors, wavelength) is adjusted according to the laser (energy, wavelength,...).

For security, tunable chameleon products are of interest as sensors, especially to inform of repeated or prolonged exposure to ultraviolet excitation.

![]()

CONTACT US

We will get back to you as soon as possible..

"*" indicates required fields