The 1st challenge: choosing the right family of materials

Today, there are various intelligent molecules (pigments and dyes) on the market. Some smart molecules have been known for decades. However, it is important to think carefully before choosing a generation of chameleon materials: thermochromic, photochromic, piezochromic, chemochromic...

Some processes are extremely fragile and have a very limited light resistance to ultraviolet exposure (like thermochromic leuco-dyes), which greatly reduces the use of these leuco-materials in outdoor conditions.

Some of thermochromic leuco-dyes also contain restricted substances, such as Bisphenol A (BPA) molecules and/or toxic metals that will severely limit the end use.

Some color changing products are available for a test, but the industrialization of a material which changes color over the long term, with the obtaining of identical batches in property, can quickly prove to be problematic.

The 2nd challenge: mastering the color change in the finished product

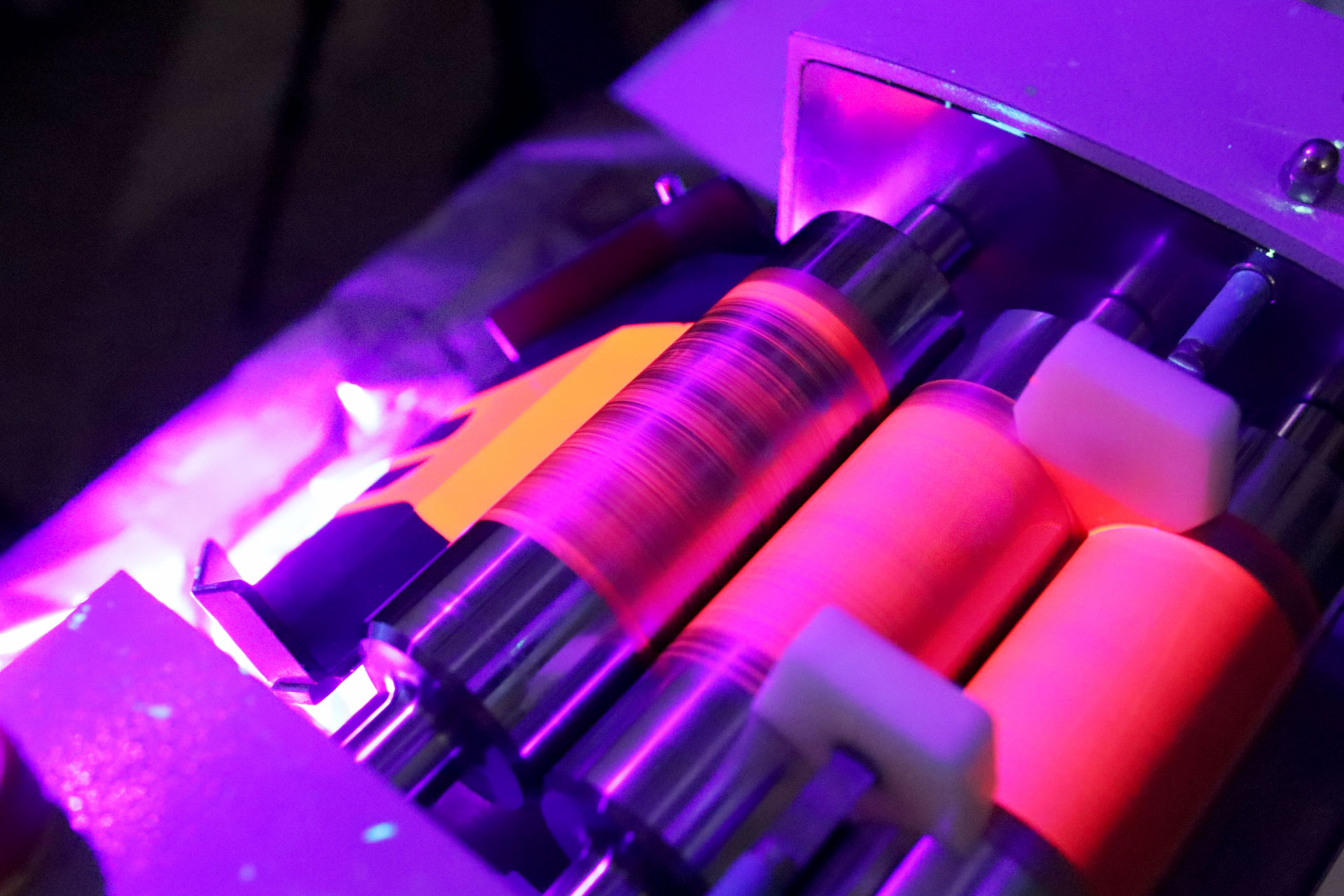

These intelligent materials are extremely sensitive to their environment and too many industrial developments are currently halted by a lack of understanding of the thermodynamic processes involved in color transition. The milling and formulation steps modify the physico-chemical environment of the intelligent pigments and leuco-dyes.

Consequently, it is essential to control the property at each stage, until the finished material. For this, it is necessary to use absorption and fluorescence spectrometers, diffuse reflectivity devices to follow the color changes according to the temperature, to investigate the excited state hyper-surface involved along the optical excitation...

The 3rd challenge: to program the color change properly

The existence of several physical processes involved in the color change allows, if they are well controlled, to adapt to industrial demands. It is a real programming of the pigment so that the change of colors intervenes in a reversible or irreversible way, at a defined threshold of disturbance.

It is also advisable to take into account the fatigability of the chameleon material in its final use, namely, the duration of the phenomenon (number of cycles of switching the temperature, the light...), speed of the phenomenon (round trip)...

The 4th challenge: hoping for a finished product "off the shelf"

To save time, the OliKrom team is often asked to order a finished product "off the shelf" to satisfy an industrial need, some applications. The reality is quite different!

Each specification has its own particularities, such as the intelligent property required, the shaping requirements during the industrial process, the desired durability or the regulatory aspects... Each of these elements is essential for our researchers team to synthesize the right pigment and formulate the optimal solution (paint, ink,...).

The consequence of a wrong selection is the rapid degradation of the properties of Chameleon response (changes of the color with temperature, light...), or the performance of the luminescence, fluorescence, phosphorescence...

To meet industrial specifications, OliKrom has acquired international recognition in the field of SmartKrom® and color intelligence for industrial safety. Every day, our researchers create and produce thermochromic, photochromic and piezochromic compounds...

To meet industrial specifications, OliKrom has acquired international recognition in the field of SmartKrom® and color intelligence for industrial safety. Every day, our researchers create and produce thermochromic, photochromic and piezochromic compounds...