The risks of hydrogen leaks

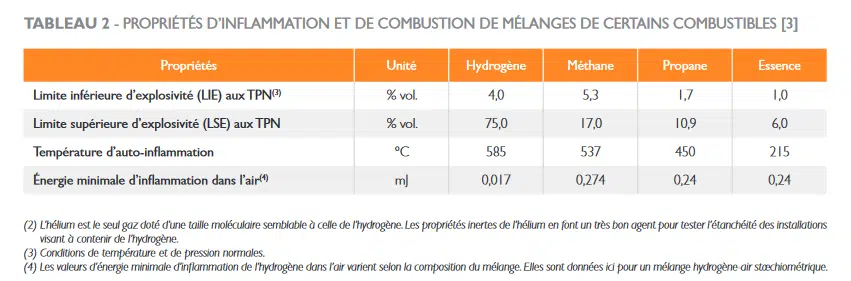

Taking into account the flammability of hydrogen is an omnipresent problem in industry for the protection of people and equipment, both on production and energy transformation sites and during transport or storage.

In all cases, the risks of leakage are significant. According to scientific estimates, the production and use of one ton of hydrogen could release between 5 and 30 kg of this gas. This range would have the same impact on the climate as 1 to 6 tons of CO2.

Hydrogen being a very flammable gas, the dangers of explosion and fire are real and can have great consequences.

A challenge of training and awareness

Whatever the emerging uses, the handling of a highly flammable gas requires awareness and training for many players.

Everyone, at their own level, must be aware of the need to make industrial sites safe, whether they are neophytes or already have experience with other types of energy (natural gas, for example).

This awareness-raising process should involve all players: manufacturers of storage units (tanks, batteries), mobility players (automotive, rail, air & space, etc.), infrastructure installers (distribution, recharging stations), not to mention contractors in charge of their maintenance.