Luminescent material: pigment, ink, paint

Are you looking for a luminescent product?

OliKrom is an internationally recognized player in the field of luminescent, phosphorescent and fluorescent technology.

Every day, on demand, we design and produce high performance inks and paints with optimal luminous properties. We operate in all industrial sectors: aeronautics, food, automotive, construction, cosmetics, defense, energy, luxury goods, medical, transportation...

Our factory ensures the industrial production of luminescent materials in compliance with our commitment to quality (ISO 9001 certification) and security of supply.

15 years of expertise in color intelligence

Our Customized photoluminescent coatings

In the world of luminescence, we have made the strategic choice of "custom-made products". Examples of commercial photoluminescent compounds are numerous, as are the photophysical processes. However, each technology has its advantages and limitations.

We put at your disposal our 15 years of experience in photochemistry, material science and formulation to design and produce your photoluminescent paint & ink adapted to your application and your deposition technique (screen printing, spray...).

We distinguish between fluorescence, which stops as soon as the illumination stops, and phosphorescence, which persists.

- Concretely, the rapidity of fluorescence is due to a de-excitation mechanism between an excited state and a ground state of the same multiplicity (ΔS=0) which respects the selection rules of photon emission of quantum mechanics. At the molecular scale, the transition occurs between a singlet S1 state and the ground state S0 without a change in multiplicity.

- Phosphorescence is a phenomenon of de-excitation between two states of different multiplicity which is not allowed by the quantum model, but is made possible by the spin-orbit coupling. The phosphorescent transition is consequently slow to take place. In molecular chemistry, the phosphorescence process is generally encountered during the relaxation between an excited state T1 (triplet) and the ground state S=0, involving a change of multiplicity.

Looking for an ultra-luminescent ink or paint?

By experience, we know the main pitfalls encountered with luminescence: the choice of the physical process, the impact of the colors, the loss of properties (low performance) during the formulation and/or the industrial process, the sensitivity to ultraviolet rays, the low coloring power, etc.

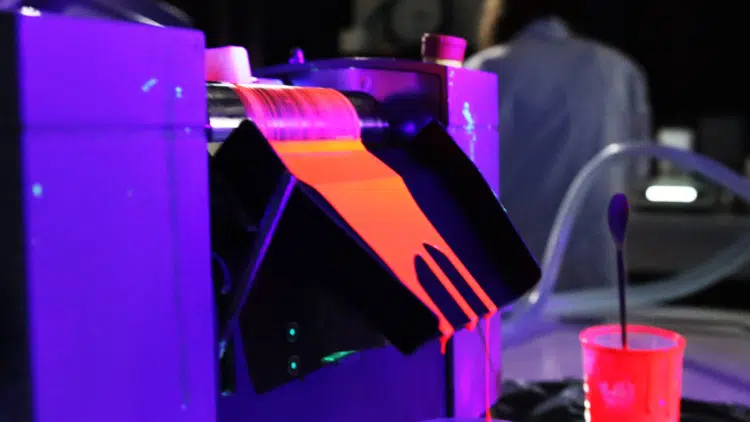

Luminescent ink

Nature : solvent-based or UV photocurable ink

Support : to be defined according to the project

Application : Screen printing - Flexography - Pad printing

Luminescent paint

Nature : solvent or aqueous phase

Support : to be defined according to the project

Application : Spray - Brush - Roller - Aerosol can

We create our own pigments, dyes and deliver our products in the form of inks and varnishes to guarantee the luminous performance on its support.

Depending on your project, our teams have the ability to adjust the fluorescence properties for a revelation in the dark at 265 nm, 365 nm, 380 nm, 390 nm, 405 nm.

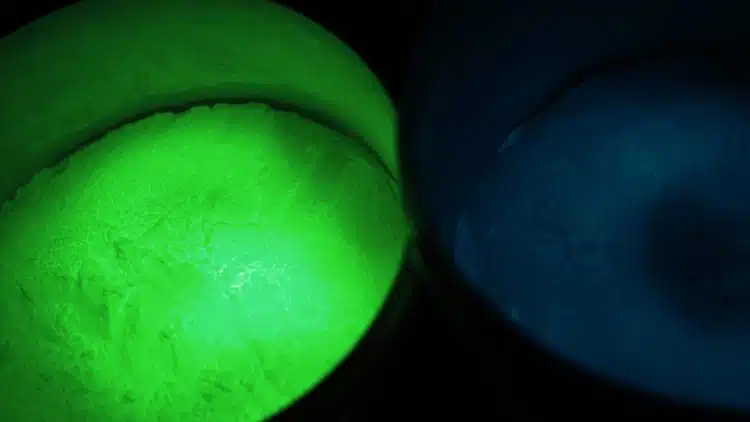

We also adapt the phosphorescent product to offer a wide range of day/night colors with optimal luminescence properties.

All our high performance products are produced at our ISO 9001 certified industrial site in Pessac, France, following rigorous manufacturing processes and under the continuous supervision of our quality manager.

A specific luminescent request adapted to your application?

Our team masters all photoluminescent compounds: organic, hybrid and inorganic. This agility allows us to select the best generation of luminescence according to your request.

We have at our disposal a set of ultra-luminous elementary bricks. Through molecular engineering, we program the product to control the photochemical cascade in the excited state, the light energy and optimize the quantum yield of luminescence.

We also adapt the luminous technology according to your application as well as the Day and Night color (emitted light).

Our fluorescent materials

Optimal formulation of coatings with super luminous properties. Adjustment of the excitation wavelength in the ultraviolet, visible and/or infrared range.

Optimization of the light intensity at different colors: blue, green, yellow, red...

Our phosphorescent materials

Optimized formulation of phosphorescent coatings capable of reaching a luminescence of more than 10 hours. Adjustment of the excitation wavelength in the ultraviolet, visible and/or infrared range.

Modulation of the daylight and glow in the dark: blue, green, yellow, red...

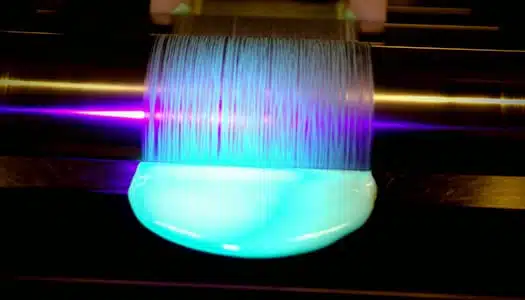

Performance control at each step from pigment to luminescent materials

At each stage, the luminescence of all our pigments, inks and paints are systematically controlled and validated:

- the emission spectrum gives access to the variation of the intensity of the emitted light according to the wavelength;

- the quantum yield informs on the performance of the material. It varies from 1 (all absorbed photons are re-emitted) to 0 (the compound is not luminescent);

- the luminescence lifetime is the characteristic time of emission of photoluminescent materials (inks and paints). In most cases, the emission is described by an exponential probability law in exp (- t/τ), where τ is the lifetime. The order of magnitude of the lifetime of many fluorescents is the nanosecond (billionth of a second). For a phosphorescent material, the lifetime can be several hours.

Our team is composed of doctors, engineers and technicians experts in chemistry. We are at your disposal to adjust :

- the luminous performance (emitted light),

- The nature of the colors (day and night light),

- The insertion of pigments in a formulation adapted to your substrate and your deposition technique without altering the properties (screen printing, spray...),

- Secure industrial-scale production.

Each development is unique. All of our solutions meet specific criteria: desired effect, shaping during the industrial process, desired durability, regulatory aspects, economic dimension...

Throughout the development process, our team will accompany you from the idea to the final product, in order to intervene efficiently at each stage of your project: R&D, pre-industrialization and industrialization.

Fluorescent coatings

The use is frequently encountered in our daily life. For example, detergents contain "optical brighteners", as does paper. These are compounds that emit a blue light to compensate for yellowing and give an "impression of whiteness".

There is also a multitude of "fluo": markers, decorative accessories for children, spray cans, clothing, stickers, inks and paints, varnishes ... Banknotes are also marked with molecules that can be activated with a small UV (ultraviolet) portable lamp. Our teams intervene in the field of anti-counterfeiting in all discretion, do not hesitate to contact us.

Fluorescence is also an extremely sensitive analysis tool, used in particular by the scientific police as well as for industrial security. It can be used, for example, for the detection and dosage of pollutants (such as lead, cadmium, mercury), but also molecules of biological interest (such as glucose), gases (O2, CO2, NO...), traces of explosives...

Its use is also important in the medical field. This diagnostic method is used for some cancers (bladder, breast), to visualize arteries and veins (angiography), to follow the concentration of useful - or harmful - substances in blood or urine,...

Phosphorescent examples

Glow in the dark applications are now widely deployed in the field of decoration: inks, stickers, spray cans, adhesives, phosphorescent stars on the ceiling for children...

In the field of security, we have deployed the patented LuminoKrom® technology, a phosphorescent road marking capable of emitting more than 10 hours in the dark.

LuminoKrom® paint charges naturally during the day in sunlight (or artificially in light from any optical source) and illuminates a green light at night without any electricity consumption or CO2 emissions

Since 2018, a large number of local authorities and infrastructure managers have taken up this innovation, in France and internationally. Bicycle paths, pedestrian walkways, locks, traffic circles, crosswalks etc. are equipped with this phosphorescent marking. Other uses concern industry and the evacuation of operators in the event of a power cut: interior signage in buildings, emergency exits, identification of dangerous areas.

Its unique ultra-luminescent properties make it a real asset for the infrastructures of tomorrow. LuminoKrom® glow in the dark is an autonomous, renewable energy, economical and eco-sustainable signage.

![]()

CONTACT US

We will get back to you as soon as possible..

"*" indicates required fields