Create intelligent packaging

Stimulating innovative intelligent packaging for the future

OliKrom company is the specialist in intelligent materials with color change.

In the near future, packaging will be intelligent! Able to monitor the condition and quality of a product and inform the consumer directly.

No need to use digital technology on products: a smart ink react autonomously according to temperature (or light, humidity...) to produce intelligent packaging of conformity, expiry, good use...

The numerous food poisoning or products recalls of the last few years have highlighted quality issues and cold chain breaks. The use of "smart packaging" on food products is becoming an imperative for quality control, especially for local authorities when providing schools, for example, but also to reassure the consumer. Not to mention the fight against food waste and losses resulting, among other things, from inefficient packaging worldwide.

These developments in innovative intelligent packaging are also of interest to the pharmaceutical sector where, once again, the quality of a drug or vaccine is essential before it can be used. Addressing the consumer directly is one of the major challenges of our time and the advent of intelligent packaging offers multiple applications.

Do you want to develop intelligent packaging solutions? The reasons are diverse: sustainable development, need for innovation, product design, improved safety, traceability & quality, interactivity. Our expert in smart materials are at your side.

Our smart products to create colors changing inks and paints

Design of innovative and intelligent packaging with food preservation indicator

Knowledge of the thermo-stability of a vaccine or food is essential to ensure its proper consumption and even its safety and efficacy.

As a leader company in smart materials, we have a perfect command of the world of thermochromic products, capable of changing colors with temperature. Depending on the intelligent packaging need, we design and produce intelligent pigments, inks and coatings with reversible, irreversible or memory effects.

For example, it is possible to develop a intelligent packaging to track the exposure of a vaccine to temperatures above +8°C. In this case, our teams design and produce the thermochromic pigment and ink that is placed on the intelligent packaging to inform the customer, by a simple change of colors of the intelligent packaging that the temperature is exceeded.

Everything happens in the intelligent ink setting on the intelligent packaging. It is a "chameleon" process that does not require any electricity. The colors change only occurs when the defined threshold is crossed.

The use of these intelligent packaging allows to address the unique object. The implementation of such intelligent packaging on the product is simple. It can be generalized to monitor the stability of a product (food, vaccine...) on an individual scale and at low cost.

Create a good consumption indicator with a smart packaging

Our expertise in the field of color intelligence allows us to produce intelligent inks and varnishes with reversible colors change to create intelligent packaging in the food industry.

Your innovative smart packaging changes color with temperature to attract attention, interact with the consumer, and provide an element of comfort in his consumption.

Some examples of food applications for the consumer's benefit:

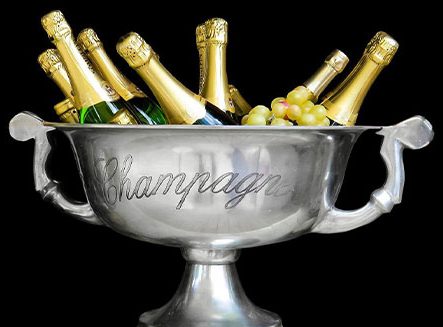

- on bottles containing a drink, to indicate if it is cool enough to be consumed (wine, champagne...),

- on intelligent packaging (pizza boxes, ready meals...) and smart labels (ready-to-eat sauces...) to indicate when the food product has been sufficiently heated,

- on kitchen utensils or childcare products (coffee cups, water bottles, baby bottles, bathtubs...) to indicate that the food content is too hot and thus alert the consumer to the danger of burning.

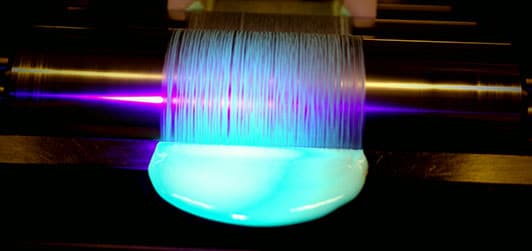

Check the sterilization of products with a intelligent packaging

Our teams are frequently asked to develop customized smart packaging with new features. For instance, in the field of security we develop and produce smart inks that change color to indicate that a temperature threshold has been crossed during the sterilization process (steam, temperature, autoclave, gamma ray, etc.).

More precisely, when the temperature of the steam in a disinfection cabinet exceeds 120°C, the label made of our thermochromic ink changes color (for example from red to white), indicating if the sterilization process has reached its term.

Depending on the need, the color change can last a few minutes and return to its initial state, or become irreversible for a permanent marker.

Do not hesitate to contact our experts of smart materials to study your project of innovative smart packaging. We have a wide range of colors (blue, red, yellow, green, black...), temperatures and deposition techniques (screen printing, flexography, pad printing, spray....).

A wide variety of color change materials for intelligent packaging

Smart materials with color change and/or optimized luminescence are an opportunity to develop a multitude of smart packaging.

The color of an product is no longer fixed, it can change with its environment and be parameterized according to the need to appear and/or disappear, adapting to day or night.

Our unique expertise in color intelligence allows us to program the smart product to make the intelligent packaging sensitive to heat, light (photochromic and luminescence materials), pressure (piezochromic products), the presence of a solvent or a gas (chemochromic materials).

During the design of the intelligent packaging on the targeted product (medicine, vaccine, food...), we will adjust its reversible or irreversible character, the speed of switching, the threshold of change, the nature of colors....

![]()

CONTACT US

We will get back to you as soon as possible..

"*" indicates required fields