Le changement de couleur

Sensibles, réactifs, ces matériaux dits intelligents se transforment et changent de couleur sous l'influence de la chaleur, de la lumière ou d'une stimulation mécanique (étirement, impact).

Par ingénierie moléculaire, la réactivité du matériau est programmer pour induire une modification des propriétés optiques en fonction :

Par contre, l'erreur première est de considérer que ces pigments intelligents sont des additifs classiques à ajouter à une peinture, une encre,... Sans un minimum de précaution, la sanction sera la dégradation des propriétés caméléons.

Ces pigments intelligents mettent en jeu des phénomènes de transition de phase liés à des mécanismes de modification structurale d'isomérisation, de cyclisation (ou ouverture de cycle), de transfert d'électrons, de protons, d'atomes d'hydrogène et/ou d'état de spin...

La modification de coloration est nullement de la magie !

Le 1er défi : bien sélectionner le pigment à couleur adaptative

Il existe aujourd'hui sur le marché plusieurs générations de produits à changement de couleur : pigment, encre et peinture... Certains pigments caméléons sont connus depuis plusieurs dizaines d'années.

Il convient toutefois de bien réfléchir avant de sélectionner une génération de matériaux intelligents.

Certains processus sont extrêmement fragiles et ont une tenue lumière très limitée à l'exposition des ultraviolets, ce qui réduit fortement l'usage de ces matériaux en condition extérieure.

D'autres contiennent des substances à usage restreint, à l'exemple du bisphénol A (BPA) et/ou des métaux toxiques qui limiteront fortement l'usage final.

Le 2ème défi : maîtriser le changement de couleur

Ces pigments intelligents sont extrêmement sensibles à leur environnement et trop de développements industriels sont aujourd'hui stoppés par une méconnaissance des mécanismes thermodynamiques impliqués au cours du phénomène de transition de phase.

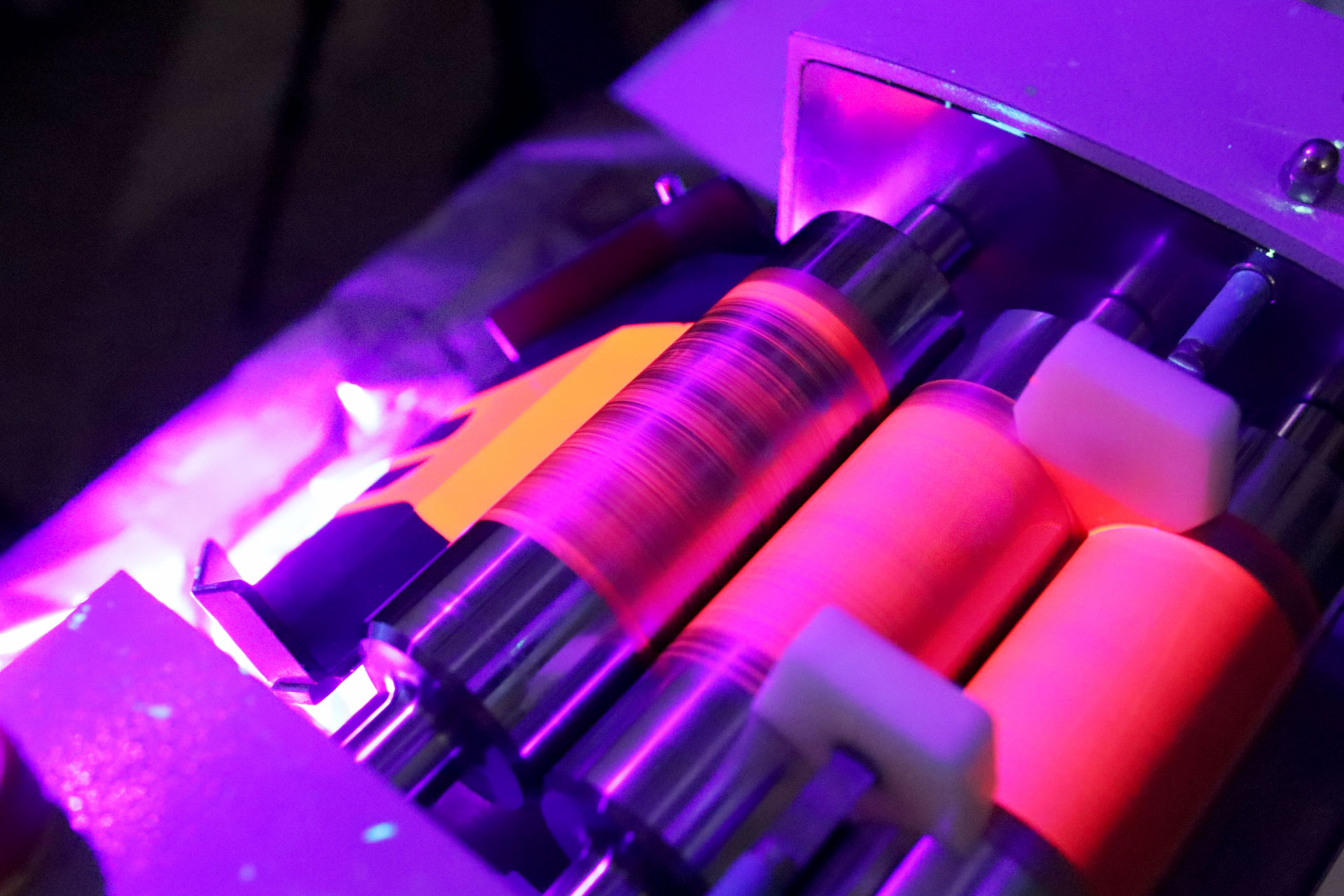

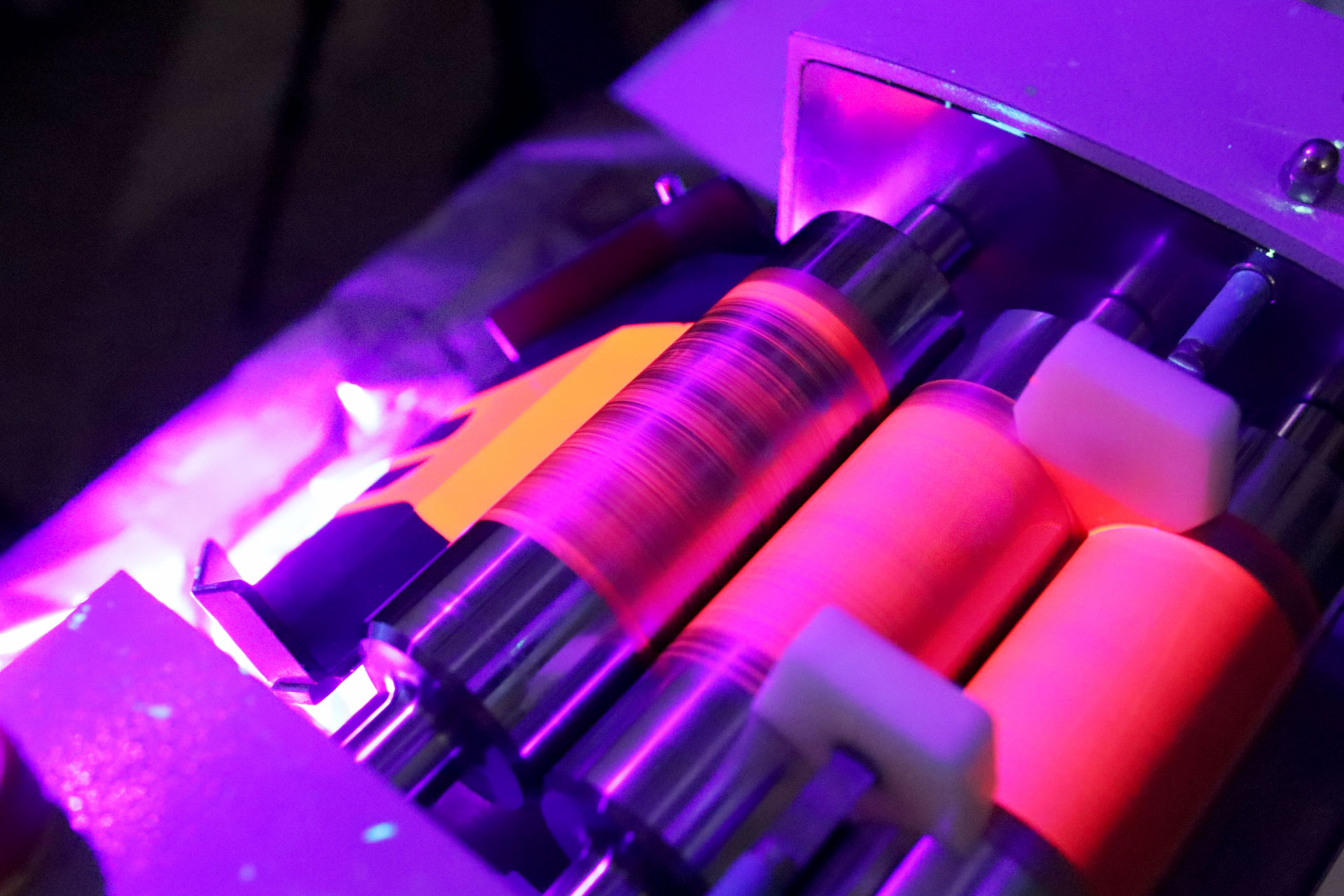

Les étapes de broyage et de formulation modifient l'environnement physico-chimique des pigments. La propriété intelligente doit être contrôlée à chaque étape (couleur, luminescence...), jusqu'au revêtement ciblé (encre & peinture).

Pour cela, il convient d'utiliser des spectromètres d'absorption et de fluorescence, des appareils de réflectivité diffuse permettant de suivre la modification de couleur en fonction de la température, colorimètre (évaluation de la coloration, de teinte de la matière), luminancemètre (pour l'évaluation de la luminance)...

Le 3ème défi : bien programmer le changement de couleur

L'existence de plusieurs mécanismes physiques permet, s'ils sont bien maîtrisés, de s'adapter aux demandes industrielles.

Le défi réside dans la programmation du pigment pour que la modification de couleurs intervienne de façon réversible ou irréversible, à un seuil de perturbation défini.

Il convient également de prendre en compte la fatigabilité du matériau intelligent dans son usage final, à savoir, la durée du phénomène de modification de couleur (nombre de cycles), la rapidité du phénomène (aller-retour), la tenue lumière...

La mauvaise sélection, ou l'oubli d'un critère, sera irrémédiablement sanctionnée.

Le 4ème défi : espérer un produit fini "sur étagère"

On demande souvent à l'équipe OliKrom, pour gagner du temps, de commander une matière finie "sur étagère" pour satisfaire un besoin industriel. La réalité est toute autre !

Chaque cahier des charges a ses particularités au regard, par exemple, de la propriété SmartKrom® recherchée, de la coloration (teinte, pouvoir couvrant...), des exigences de mise en forme au cours du process industriel (encre, peinture...) et des techniques de dépôts (sérigraphie, tampographie, spray...), de la durabilité souhaitée ou encore des aspects réglementaires...

Chacun de ces éléments est essentiel pour séletionner le bon pigment à changement de couleur, le synthétiser et formuler la solution intelligente optimale (peinture, encre,...). La mauvaise sélection a pour conséquence une dégradation rapide des propriétés de changement de couleur, de la photoluminescence, une fatigabilité du système...

L'apport OliKrom : la maîtrise de la production du pigment à la formulation encre, peinture...

Pour répondre au cahier des charges industriel, l'équipe OliKrom a acquis une reconnaissance internationale dans le domaine de l'intelligence des couleurs, à savoir cet ensemble de matériaux capables de changer de couleurs, de moduler leur réponse optique, leur luminescence...

Le savoir-faire de notre équipe de docteurs et d'ingénieurs chimistes, en chimie organique, hybride et inorganique, nous permet de synthétiser, en fonction des critères recherchés, le pigment optimal, et de maîtriser l'ensemble des étapes de formulation. A chaque étape, la propriété intelligente recherchée est contrôlée.

Chaque développement industriel est réalisé "sur mesure", il n'existe pas de solution "sur étagère". Par contre, l'expérience acquise par l'équipe OliKrom dans le domaine des SmartKrom® (pigment, encre et peinture) permet de prendre en compte la dimension globale du projet en intégrant l'ensemble des facettes, depuis les propriétés caméléons recherchées (coloration...) jusqu'aux aspects industriels et réglementaires. Les dimensions technico-économiques et confidentialité sont également au cœur de notre démarche.

Pour garantir la qualité de nos produits et assurer une entière satisfaction pour nos partenaires industriels, nous distribuons uniquement les revêtements intelligents, sous forme d'encre, de peinture, de mélange-maître.