To provide the best experience, we use technologies such as cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behaviour or unique IDs on this site. Not consenting or withdrawing consent may adversely affect certain features and functions.

Storage or technical access strictly required for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.

Storage or technical access is required for the legitimate interest purpose of storing preferences that are not requested by the subscriber or user.

Storage or technical access that is used exclusively for statistical purposes.

Storage or technical access exclusively used for anonymous statistical purposes. In the absence of a subpoena, voluntary compliance by your internet service provider or additional third party records, the information stored or retrieved for this sole purpose cannot generally be used to identify you.

Storage or technical access is required to create user profiles in order to send ads, or to track the user on a website or on several websites with similar marketing purposes.

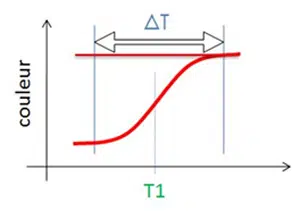

One of the reasons for using a thermochromic coating in place of a thermometer and/or thermocouple may be the need to map the temperature in an environment where it is impossible to insert any electrical wiring.

One of the reasons for using a thermochromic coating in place of a thermometer and/or thermocouple may be the need to map the temperature in an environment where it is impossible to insert any electrical wiring. Other fields call upon thermochromic materials for their capacity to act without electricity, in total autonomy. This type of demand occurs in particular for the storage of sensitive materials for years in the field of industrial maintenance (energy, petrochemical, nuclear...). In this case, electrical autonomy is a requirement.

Other fields call upon thermochromic materials for their capacity to act without electricity, in total autonomy. This type of demand occurs in particular for the storage of sensitive materials for years in the field of industrial maintenance (energy, petrochemical, nuclear...). In this case, electrical autonomy is a requirement. The thermochromic solutions approach is also selected in many sectors where unitary control is required. This is the case for example in the medical and/or food industry. Contrary to the use of a thermocouple and/or thermometer, a reversible thermochromic product with memory effect or irreversible thermochromic product allows to control the thermal evolution of an element on an individual scale, of each medicine, each packaging: to identify for example a break in the food cold chain, to attest the conformity of storage of a medicine, of a vaccine.

The thermochromic solutions approach is also selected in many sectors where unitary control is required. This is the case for example in the medical and/or food industry. Contrary to the use of a thermocouple and/or thermometer, a reversible thermochromic product with memory effect or irreversible thermochromic product allows to control the thermal evolution of an element on an individual scale, of each medicine, each packaging: to identify for example a break in the food cold chain, to attest the conformity of storage of a medicine, of a vaccine.